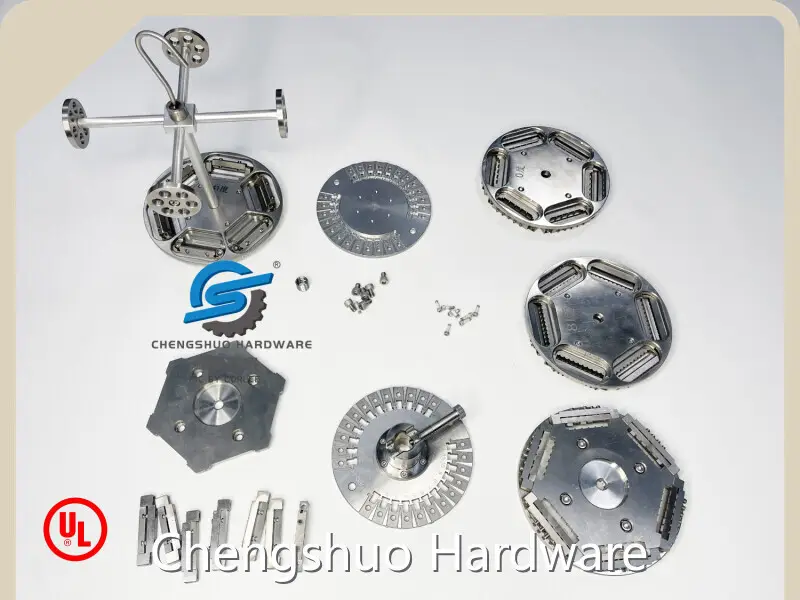

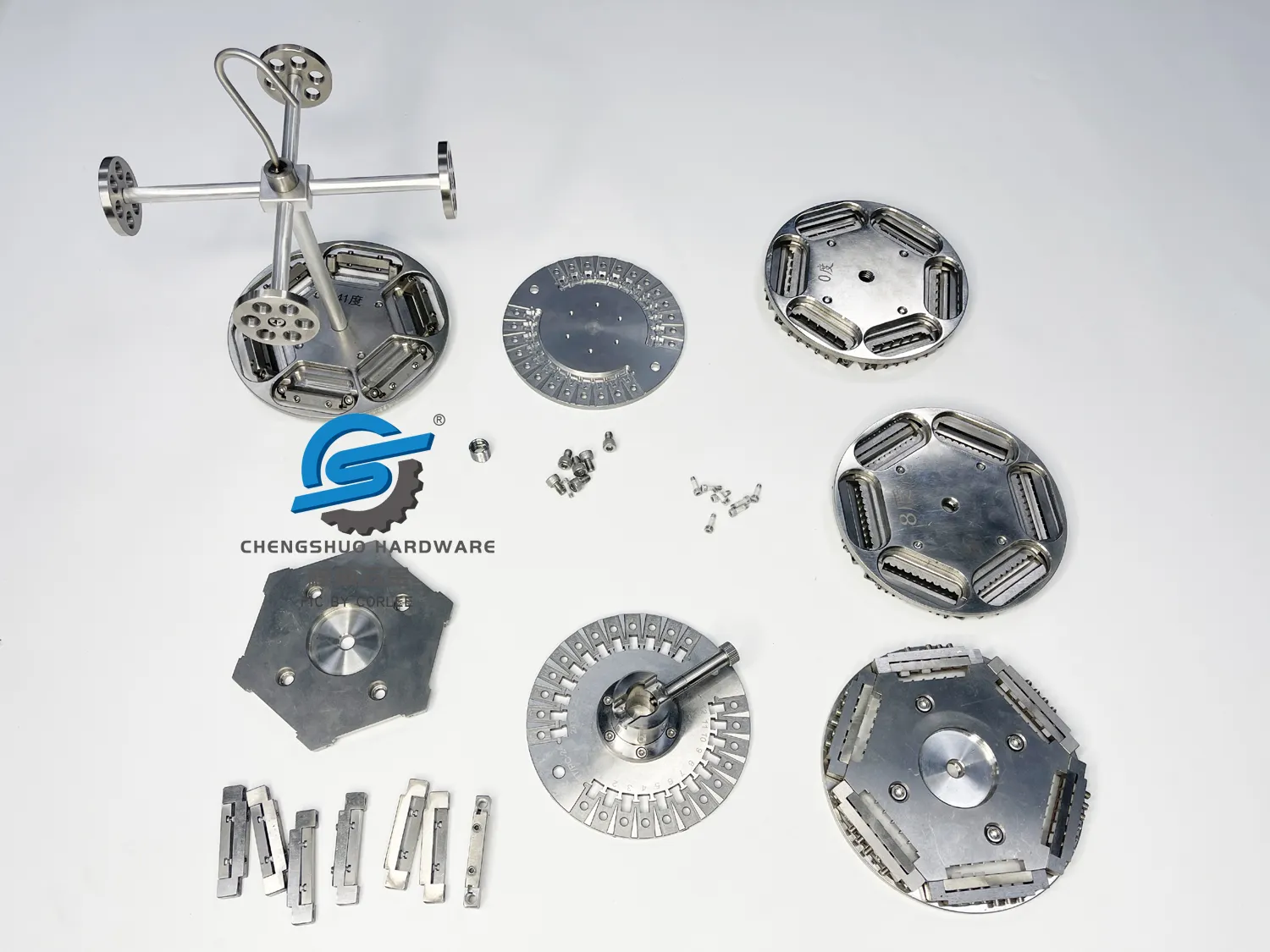

Turned Parts Supplier Aluminum by Chengshuo Hardware

Product details of the turned parts supplier

Product Introduction

Chengshuo Hardware turned parts supplier is produced by our trained professionals using high-grade raw material according to industry norms. The product has an internationally-certified quality and has a longer service life compared with others. Dongguan Chengshuo Hardware Co., Ltd will strive to satisfy customers, the general public and the people in the countries (regions) where the business is located.

Design of processing steps

1. Preliminary cutting of material into blank disc base or hexagonal base

2 rough prototypes grinding and polishing

3 CNC milling, drilling holes and making furniture accessories on the chassis

4 Five axis lathe department produces accessories

Project design

This project is developed by the Chengshuo team, Project engineer is our Chief Engineer Mr. Lei.

Other senior engineers involved in this project included:

- Supervisor Mr Tang - Grinding& Machining Department

- Supervisor Mr Liang- CNC Milling Center Department

- Supervisor Mr Li-Five axis lathe machining department of Cheng Shuo Hardware

- Mr Deng Senior Engineer of Cheng Shuo Hardware Wire Cutting

Departmental linkage production

◆ Machining and wire cutting to produce rough circular chassis.

◆ The CNC department produces chassis secondary processing, fasteners and other products.

◆ The 5-axis lathe department produces cylindrical parts.

◆ Quality Department Assembly and Inspection.

Difficulties in interviewing project leaders

◆ The project has high precision requirements and requires engineers from various departments to strictly control tolerances.

◆ There are many accessories, and the assembly is relatively complex.

Company Advantage

• Unique geographical advantages and abundant social resources create good conditions for Chengshuo Hardware's development.

• We have a broad market for our products. They are currently sold well in various regions at home and abroad.

• Chengshuo Hardware has conducted in-depth technical exchanges and cooperation with both domestic and international R&D agencies. Besides, we have also hired a number of experts to be technical advisors and regularly organized training and exchanges. All this provides a technical guarantee for the production.

Chengshuo Hardware's CNC Machining、CNC Turning&Milling、Stamping Metal Parts are available in diverse style and favorable price. If you have any needs, please leave your contact information. We will get back to you in time.