Customized Cnc Machining Small Parts Fiber Grinding Fixture Sequence Product

Customized CNC Machined Fiber Grinding Fixture Sequence Product is a series of high-precision custom fixtures designed specifically for fiber optic grinding. We use advanced CNC machining technology combined with precision manufacturing processes to ensure that the size, shape and assembly accuracy of each fixture are extreme, perfectly adapted to the various needs of fiber optic grinding. This series of products not only provides a variety of fixture designs, but also supports customized services to meet the specific process requirements of fiber optic manufacturers and R&D institutions.

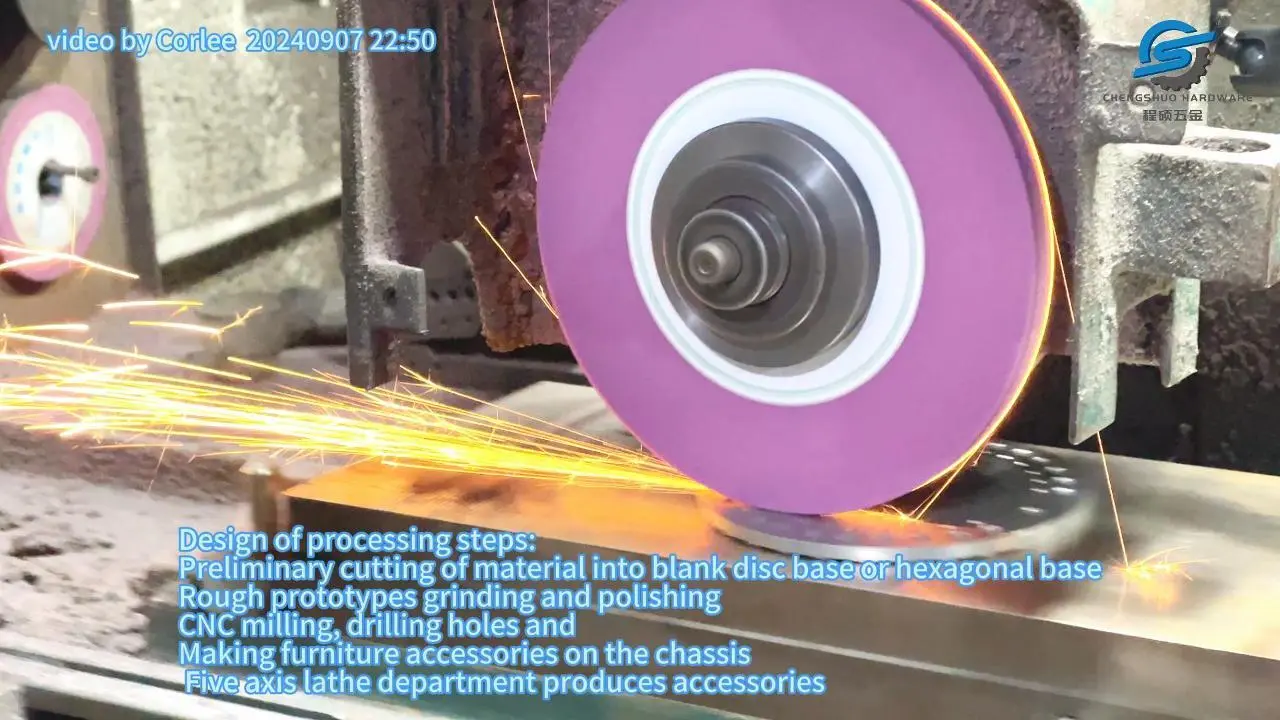

Design of processing steps

1. Preliminary cutting of material into blank disc base or hexagonal base

2 rough prototypes grinding and polishing

3 CNC milling, drilling holes and making furniture accessories on the chassis

4 Five axis lathe department produces accessories

Project design

This project is developed by the Chengshuo team, Project engineer is our Chief Engineer Mr. Lei.

Other senior engineers involved in this project included:

- Supervisor Mr Tang - Grinding& Machining Department

- Supervisor Mr Liang- CNC Milling Center Department

- Supervisor Mr Li-Five axis lathe machining department of Cheng Shuo Hardware

- Mr Deng Senior Engineer of Cheng Shuo Hardware Wire Cutting

Departmental linkage production

◆ Machining and wire cutting to produce rough circular chassis.

◆ The CNC department produces chassis secondary processing, fasteners and other products.

◆ The 5-axis lathe department produces cylindrical parts.

◆ Quality Department Assembly and Inspection.

Difficulties in interviewing project leaders

◆ The project has high precision requirements and requires engineers from various departments to strictly control tolerances.

◆ There are many accessories, and the assembly is relatively complex.