Cnc Precision Turning Electronic Consumer Products Wholesale - Chengshuo Hardware

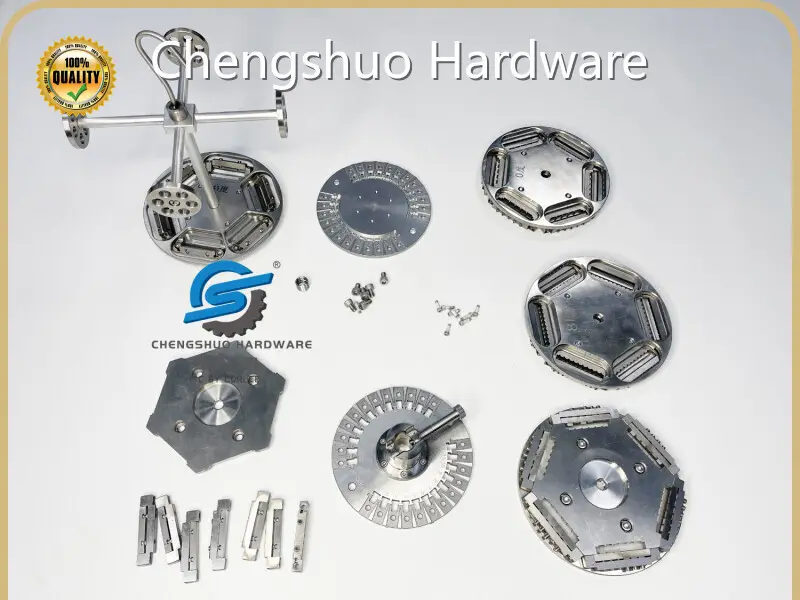

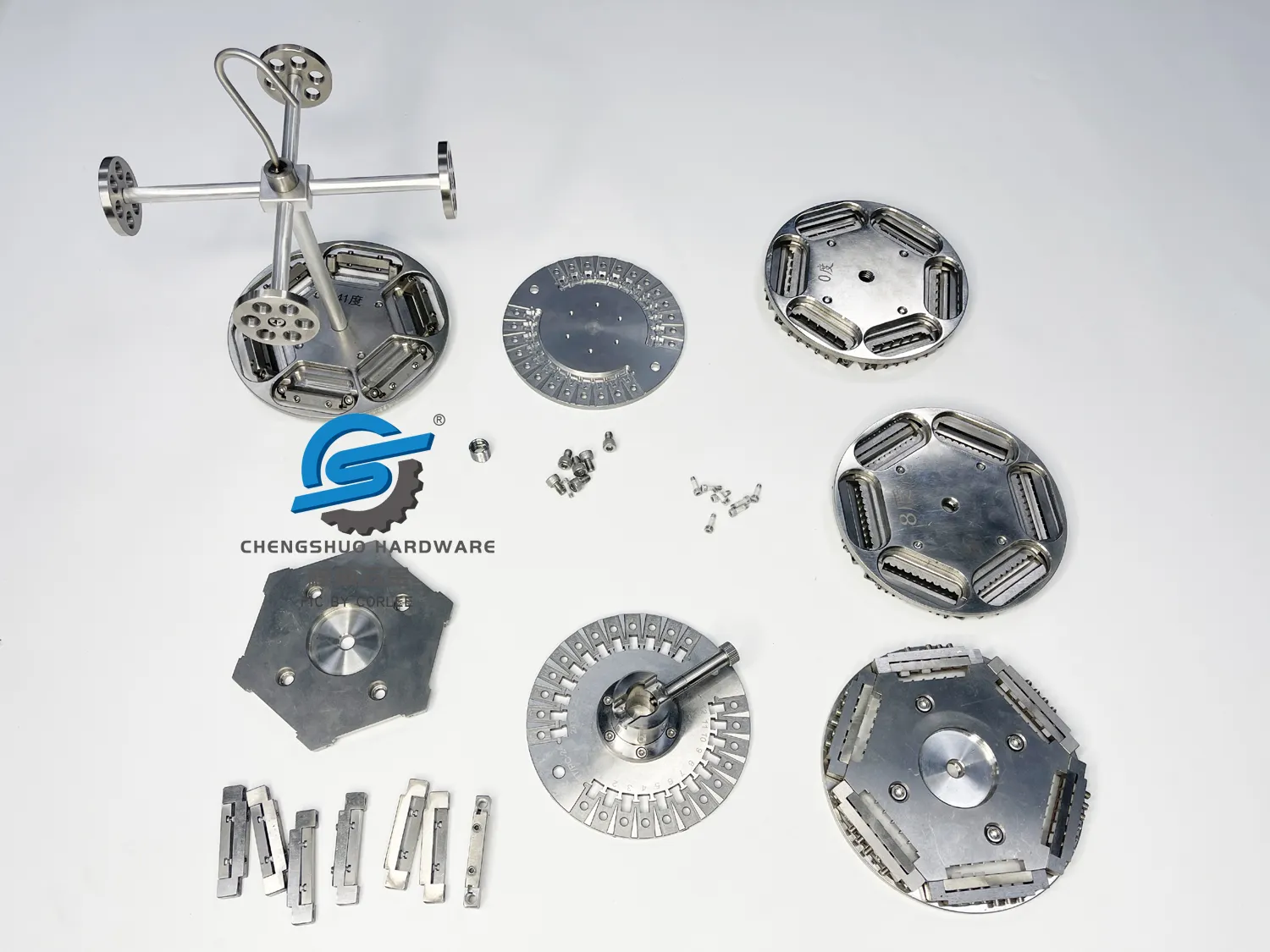

Design of processing steps

1. Preliminary cutting of material into blank disc base or hexagonal base

2 rough prototypes grinding and polishing

3 CNC milling, drilling holes and making furniture accessories on the chassis

4 Five axis lathe department produces accessories

Project design

This project is developed by the Chengshuo team, Project engineer is our Chief Engineer Mr. Lei.

Other senior engineers involved in this project included:

- Supervisor Mr Tang - Grinding& Machining Department

- Supervisor Mr Liang- CNC Milling Center Department

- Supervisor Mr Li-Five axis lathe machining department of Cheng Shuo Hardware

- Mr Deng Senior Engineer of Cheng Shuo Hardware Wire Cutting

Departmental linkage production

◆ Machining and wire cutting to produce rough circular chassis.

◆ The CNC department produces chassis secondary processing, fasteners and other products.

◆ The 5-axis lathe department produces cylindrical parts.

◆ Quality Department Assembly and Inspection.

Difficulties in interviewing project leaders

◆ The project has high precision requirements and requires engineers from various departments to strictly control tolerances.

◆ There are many accessories, and the assembly is relatively complex.

Company Advantages

· Chengshuo Hardware cnc precision turning is fabricated selecting high quality raw materials.

· We always pay attention to the industry quality standards, product quality is guaranteed.

· The fame of cnc precision turning benefits from its strict quality assurance.

Company Features

· Dongguan Chengshuo Hardware Co., Ltd is a high tech company which focuses on cnc precision turning.

· All of our exquisite goods, including cnc precision turning, are produced by our state-of-the-art machines and skilled technicians.

· While striving to provide the most satisfying products and services, we will spare no efforts to strengthen our corporate values of integrity, diversity, excellence, collaboration and participation.

Application of the Product

Our cnc precision turning is available in a wide range of applications.

With a focus on CNC Machining、CNC Turning&Milling、Stamping Metal Parts, Chengshuo Hardware is dedicated to providing reasonable solutions for customers.