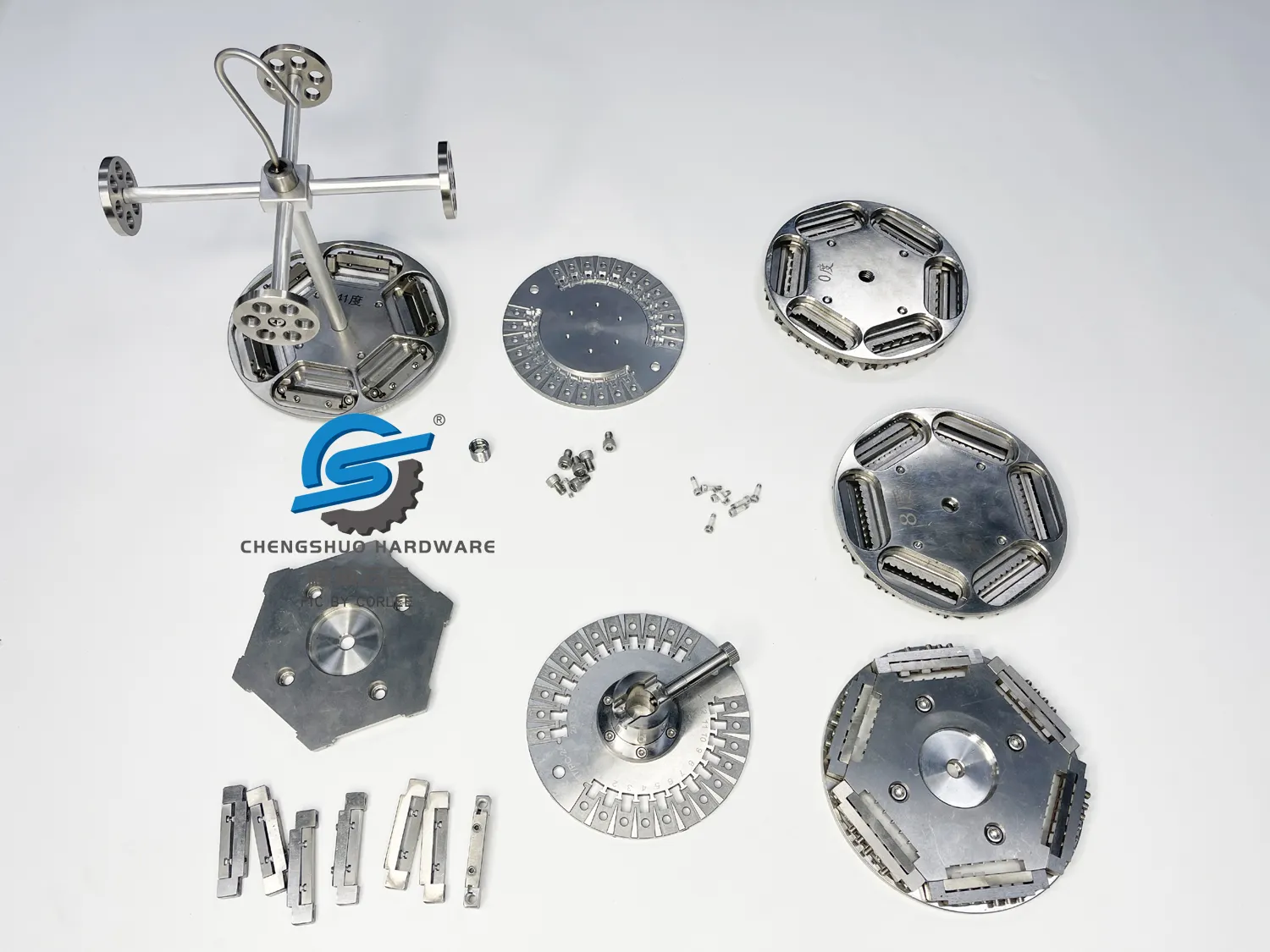

Cnc Precision Turned Components Aluminum - - Chengshuo Hardware

Product details of the cnc precision turned components

Product Information

Chengshuo Hardware cnc precision turned components is manufactured by a team of qualified experts who work with determination. Reliable quality and durability are our competitive advantages. Our focus is to offer our clients first-class, innovative and durable range of products.

Design of processing steps

1. Preliminary cutting of material into blank disc base or hexagonal base

2 rough prototypes grinding and polishing

3 CNC milling, drilling holes and making furniture accessories on the chassis

4 Five axis lathe department produces accessories

Project design

This project is developed by the Chengshuo team, Project engineer is our Chief Engineer Mr. Lei.

Other senior engineers involved in this project included:

- Supervisor Mr Tang - Grinding& Machining Department

- Supervisor Mr Liang- CNC Milling Center Department

- Supervisor Mr Li-Five axis lathe machining department of Cheng Shuo Hardware

- Mr Deng Senior Engineer of Cheng Shuo Hardware Wire Cutting

Departmental linkage production

◆ Machining and wire cutting to produce rough circular chassis.

◆ The CNC department produces chassis secondary processing, fasteners and other products.

◆ The 5-axis lathe department produces cylindrical parts.

◆ Quality Department Assembly and Inspection.

Difficulties in interviewing project leaders

◆ The project has high precision requirements and requires engineers from various departments to strictly control tolerances.

◆ There are many accessories, and the assembly is relatively complex.

Company Advantage

• Chengshuo Hardware's development is guaranteed by the good external conditions, including superior geographical location, traffic convenience, and abundant resources.

• With the aim of 'completely satisfying the customer', our company tries our best to offer the most satisfactory service to the customer.

• Chengshuo Hardware, set up in becomes a dominant company in the industry after rapid development for years.

Chengshuo Hardware's tools are of good quality and reasonable price. Your call, consultation, visit and guidance are sincerely welcome.