Brass Cnc Turned Components Aluminum - - Chengshuo Hardware

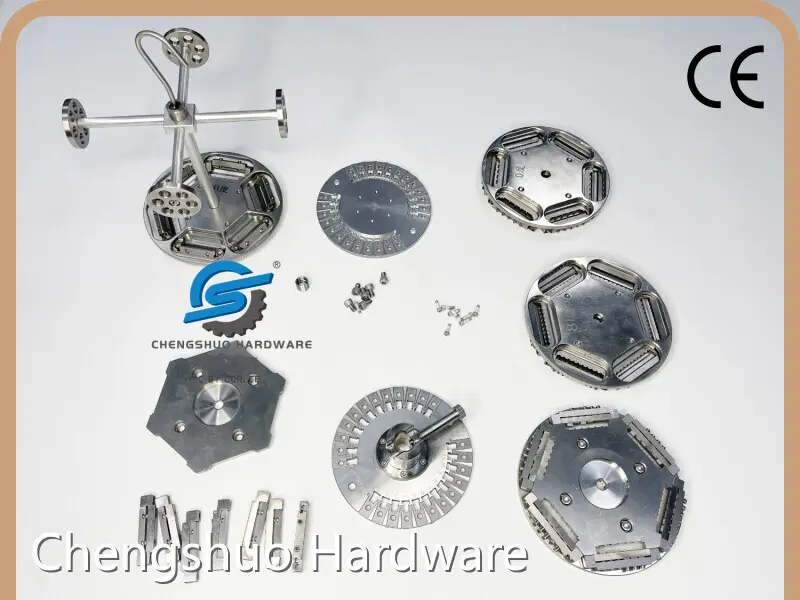

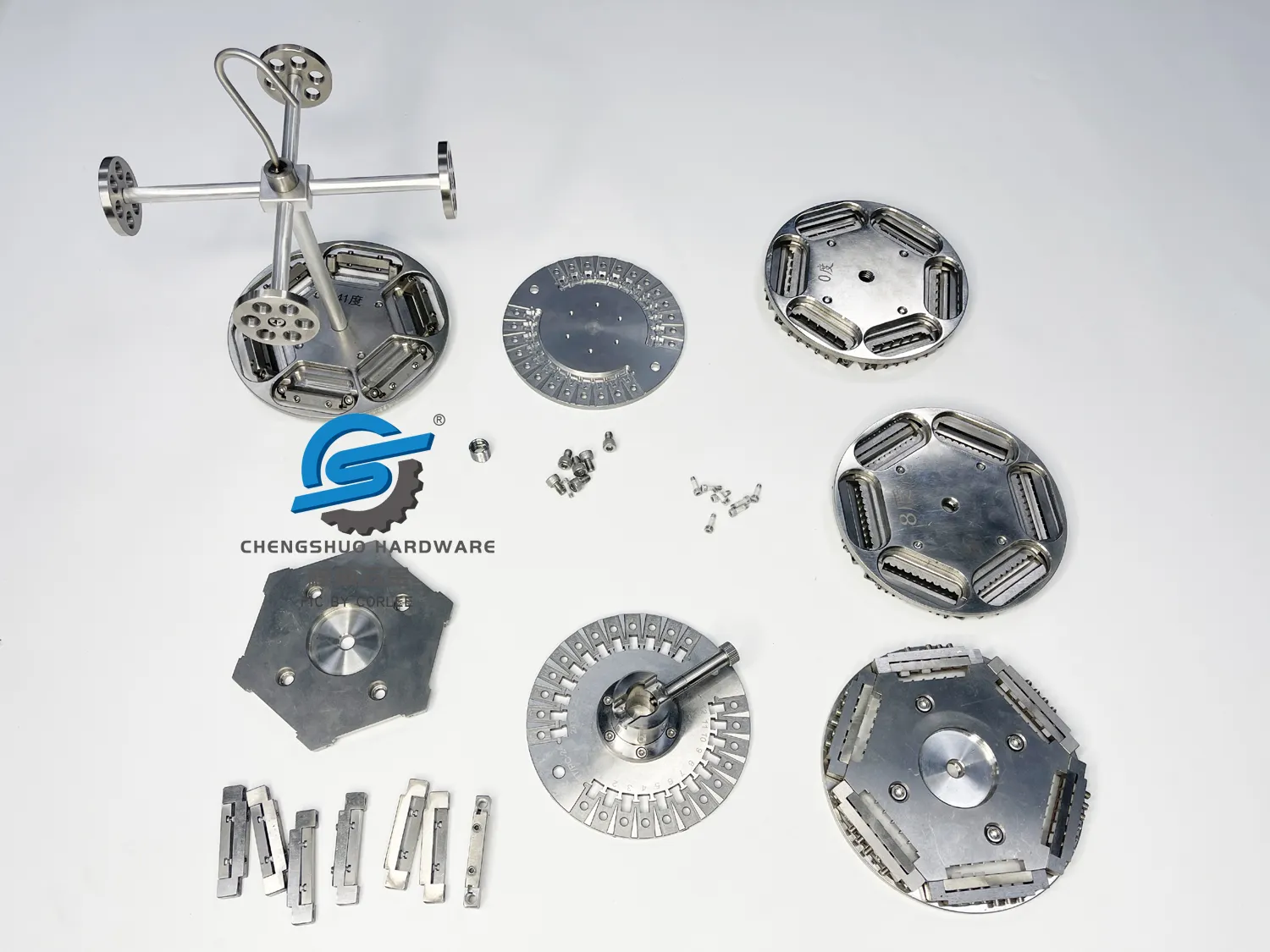

Product details of the brass cnc turned components

Product Introduction

Dissipation factor is small for brass cnc turned components. This product has a long service life and many other technical advantages. All these features provide probability for abroad application of this product.

Design of processing steps

1. Preliminary cutting of material into blank disc base or hexagonal base

2 rough prototypes grinding and polishing

3 CNC milling, drilling holes and making furniture accessories on the chassis

4 Five axis lathe department produces accessories

Project design

This project is developed by the Chengshuo team, Project engineer is our Chief Engineer Mr. Lei.

Other senior engineers involved in this project included:

- Supervisor Mr Tang - Grinding& Machining Department

- Supervisor Mr Liang- CNC Milling Center Department

- Supervisor Mr Li-Five axis lathe machining department of Cheng Shuo Hardware

- Mr Deng Senior Engineer of Cheng Shuo Hardware Wire Cutting

Departmental linkage production

◆ Machining and wire cutting to produce rough circular chassis.

◆ The CNC department produces chassis secondary processing, fasteners and other products.

◆ The 5-axis lathe department produces cylindrical parts.

◆ Quality Department Assembly and Inspection.

Difficulties in interviewing project leaders

◆ The project has high precision requirements and requires engineers from various departments to strictly control tolerances.

◆ There are many accessories, and the assembly is relatively complex.

Company Feature

• Chengshuo Hardware can provide high-quality and efficient management consulting service for customers at any time.

• Our company is located in a position with convenient transportation and thorough basic facilities nearby. All that provides a great opportunity for our company's highly developing process.

• Chengshuo Hardware's products are mainly exported to Europe and the United States. They are highly praised by local businesses and users.

• Chengshuo Hardware was founded in For years, we have always insisted on independent innovation and have maintained vigorous development. Now we are a leading company in the industry.

Leave your contact information and Chengshuo Hardware will provide you with the latest sample for free!