Customized CNC Lathe Machined Parts Motorcycle Screws Bolts Accessories

Customized CNC Machined Motorcycle Accessories Screws are high-quality custom screws for motorcycle accessories. We use advanced CNC machining technology to ensure that the size, shape and thread accuracy of each screw are impeccable, with high strength and corrosion resistance. In order to meet the diverse needs of motorcycle manufacturers and modifiers, we provide a wide range of sizes, shapes and material options, with excellent craftsmanship and customized services, highlighting the unique value and professional charm of each screw.

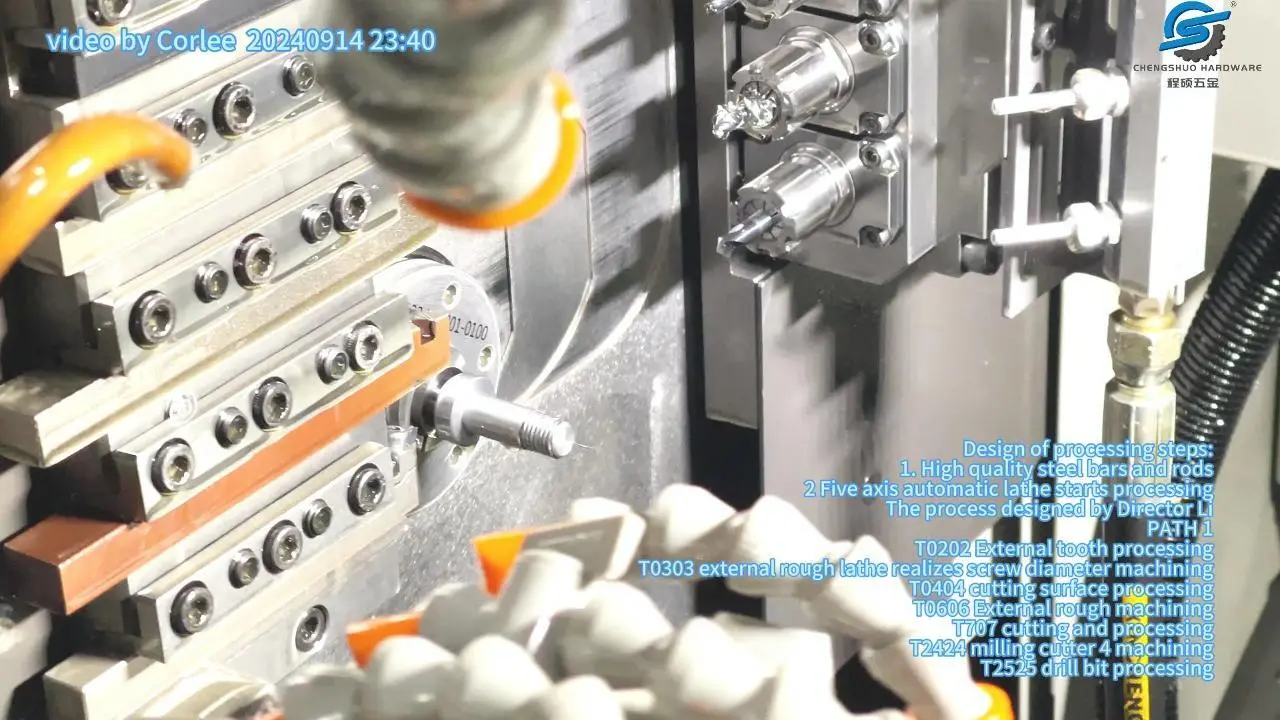

Product processing design

The process designed by cnc LATHE supervisor Mr Li

◆ PATH ONE

T0202 External tooth processing

T0303 external rough lathe realizes screw diameter machining

T0404 cutting surface processing

T0606 External rough machining

T707 cutting and processing

T2424 milling cutter 4 machining

T2525 drill bit processing

◆ PATH TWO

T3232 drill bit 7.8 machining

T3333 milling cutter 1.5 machining

T3334 milling cutter 1.2 machining

Department

This project is produced and processed by Cheng Shuo's five axis automatic lathe department, with strict requirements for thread adaptation and eagle eye machining. After precision machining, adaptation testing is required.

Difficulties after interviewing project leaders

There are many processes involved, and the tolerances are relatively precise.

Customers have strict requirements for product adaptation and installation.