Custom Spare Parts CNC Machined Circular Buckle for Earphone Shell

Customized CNC Machined Circular Buckle For Earphone Shell is a custom buckle designed for earphone shells. It uses advanced CNC machining technology to ensure precise size and shape to perfectly match the earphone shell. Its circular design is not only beautiful and stable, effectively preventing loosening and falling off, but also made of high-quality materials, with excellent durability and corrosion resistance, and can maintain performance and appearance for a long time. In addition, the customization of the buckle can also meet the special needs of different customers for size, shape and material.

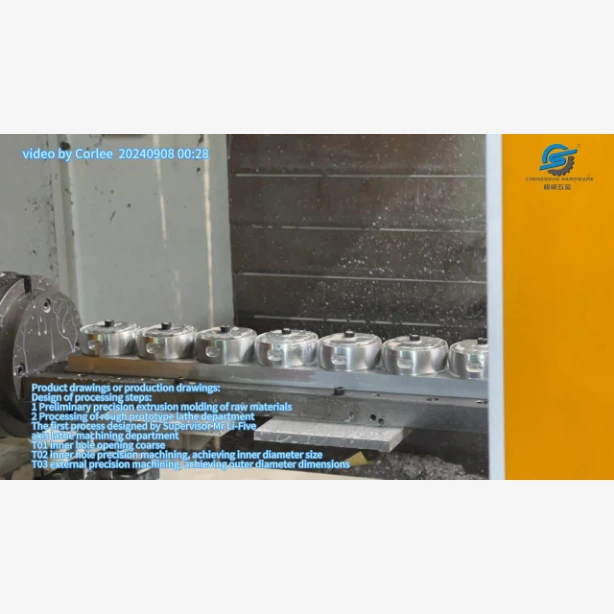

Product processing design

Departmental linkage production

This project is a combined production and processing of turning and milling by the Cheng Shuo team, with high requirements for the appearance of the product. PMC and quality supervisor work together to manage the project.

Difficulties In Interviewing Project Leaders

◆ The project requires high precision and requires engineers from various departments to strictly control tolerances to ensure product compatibility

◆ The appearance components of 2 electronic consumer goods require a high level of anodizing treatment effect and are individually packaged in vacuum formed boxes